Why Door Closers Are Essential

Door closers often go unnoticed, yet they are critical for safety, energy efficiency, and accessibility. A well-specified closer ensures doors close smoothly, prevents slamming, and complies with fire and accessibility codes. Choosing the right closer type can reduce maintenance issues and extend hardware life.

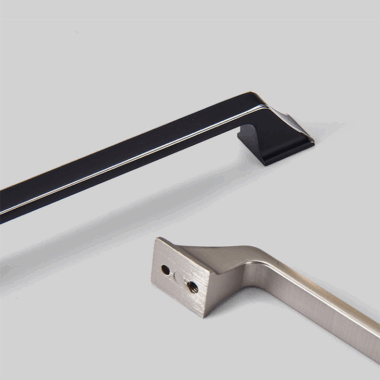

Procurement managers usually begin with dependable sourcing from a trusted Door Handle Manufacturer, ensuring all hardware components work seamlessly together.

Closer Sizing and Power Ratings

Closers are graded by size (1–6), with Size 1 for light interior doors and Size 6 for heavy exterior or fire-rated doors. Many units are adjustable, covering multiple sizes in one model. Selecting the right rating ensures controlled closing without excessive resistance.

Sweep Speed and Latch Speed Adjustments

Sweep Speed: Controls the door’s main closing motion.

Latch Speed: Governs the final few inches of travel to ensure proper latching.

Delayed Action: Keeps the door open briefly—useful in healthcare or schools.

Precise adjustment prevents slamming, reduces noise, and improves user safety.

Safety and Control Features

✔ Backcheck: Prevents damage when doors are forced open too far.

✔ Hold-Open Function: Holds the door open at a set angle (not suitable for fire doors).

✔ Soft Closing: Minimizes impact in high-traffic areas.

Contractors often reference collections from Door Closer Manufacturer where safety features are pre-listed by model.

Applications Across Industries

Schools: Require adjustable closers with delayed action for accessibility.

Retail & Malls: Prefer soft-close units to reduce noise and protect glass doors.

Healthcare: Demand hold-open or hands-free models for patient safety.

Final Thoughts

Selecting a door closer isn’t just about controlling a door—it’s about ensuring safety, compliance, and user comfort. By choosing the correct size, speed settings, and control features, builders can achieve long-term performance and reduce service costs.